Process Studies

Process consulting for Process Lines and Rolling Mills by combining the disciplines of mechanical engineering and metallurgy. Meeting the need for expert knowledge about processes, machinery, controls, and how they work together.

Providing premium technical services with our expert knowledge and world-class software.

StripCalc

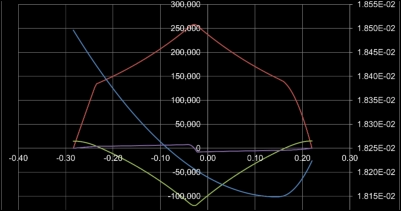

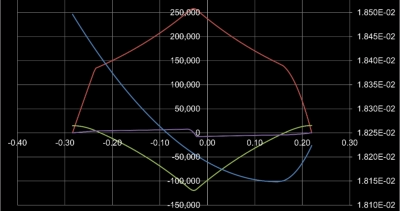

A software for calculating strip processing built on a proprietary, optimized finite-element model. Bending loss and elongation calculations incorporate strip history, strip shape and strip path to accurately simulate strip transport, tension leveling and roller leveling.

Strip Simulation

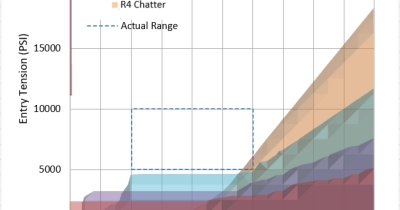

Using StripCalc and MillCalc software to build full-line strip transport and rolling models with an Excel spreadsheet front-end for off-line analysis. Process setup values can be calculated with embedded versions of the Level 2 database and Level 1 calculations or by direct link to recorded process data. Rolling forces, drive loads, and strip tension can be calculated at every location through the line. These models can be used to simulate product history or future targets.

MillCalc

A software for calculating strip rolling using a family of models built on conventional and proprietary technologies to simulate severe rolling conditions. These include: • Forward integration rolling model with fully elastic roll deflections. • Bland-Ford type rolling model with elastic zones adapted for a non-circular roll shape. • Roll flattening equations derived from an advanced non-circular rolling model. • Flexible draft scheduling for load balance. • Learning Algorithms.

StackCalc

A software for calculating rolling mill stack deflections and optimum work roll bending forces using a finite element method with Timoshenko beam elements. Using StackCalc predictions, a lightweight bending control model has been developed for on-line application in the PLC. The on-line model compensates for variable contact zones, variable roll crown and diameter.

CoilCalc

A software for calculating wrap-by-wrap coil winding to predict winding defects and optimize coiling tension practices.

Shearing Models

Using an advanced shearing model incorporating material ductility and machine stiffness to accurately analyze AHSS steel grades and/or identify machine weaknesses.

Production Simulation

Using process line production simulation software to calculate production capacities. The software models the essential process limitations, accumulators, and time cycles of a line and simulates a large schedule of coils in sequence.

Wet Process Models

Using chemical, heat, and mass transfer models to calculate pickling, cleaning, rinsing, electoplating, heating, and drying.

Strength Analysis

Using refined techniques to effectively combine finite element analysis with AWS and AGMA codes for predicting fatigue failures in complex fabricated components.Technologies

improve, everything, always

Process Studies

Providing process studies and machine analysis with proprietary technology.

Technical Services

● Process Line Tension/Strip Transport Studies ● Rolling Mill Capability ● Roll Profiles ● Mill Setup ● Leveler Capability ● Winding Optimization ● Production Capacity ● Project Development Engineering

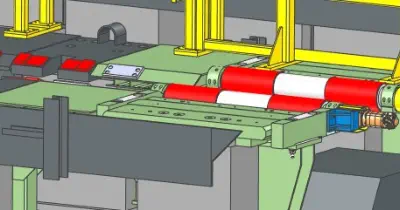

Mechanical Equipment Analysis & Redesign

● Roll and Shaft Failures ● Frame Fatigue ● Fixed and Flying Shears ● Gearing and Geared Elongators ● Overcoming Recurring Equipment Failures

On-line Process Setup and Control Models

● Tension Setup ● Rolling Mill Level 2 Rolling Model ● Rolling Mill Level 1 Bending Model

Consulting

● Problem Solving ● Upgrade and Modernization PlanningProcess

Studies

Process consulting for Process Lines and Rolling Mills by combining the disciplines of mechanical engineering and metallurgy. Meeting the need for expert knowledge about processes, machinery, controls, and how they work together.

Providing premium technical

services with our expert

knowledge and world-class

software.

StripCalc

A software for calculating strip processing built on a proprietary, optimized finite-element model. Bending loss and elongation calculations incorporate strip history, strip shape and strip path to accurately simulate strip transport, tension leveling and roller leveling.

Strip Simulation

Using StripCalc and MillCalc software to build full- line strip transport and rolling models with an Excel spreadsheet front-end for off-line analysis. Process setup values can be calculated with embedded versions of the Level 2 database and Level 1 calculations or by direct link to recorded process data. Rolling forces, drive loads, and strip tension can be calculated at every location through the line. These models can be used to simulate product history or future targets.

MillCalc

A software for calculating strip rolling using a family of models built on conventional and proprietary technologies to simulate severe rolling conditions. These include: • Forward integration rolling model with fully elastic roll deflections. • Bland-Ford type rolling model with elastic zones adapted for a non-circular roll shape. • Roll flattening equations derived from an advanced non-circular rolling model. • Flexible draft scheduling for load balance. • Learning Algorithms.

StackCalc

A software for calculating rolling mill stack deflections and optimum work roll bending forces using a finite element method with Timoshenko beam elements. Using StackCalc predictions, a lightweight bending control model has been developed for on-line application in the PLC. The on-line model compensates for variable contact zones, variable roll crown and diameter.

CoilCalc

A software for calculating wrap-by-wrap coil winding to predict winding defects and optimize coiling tension practices.

Shearing Models

Using an advanced shearing model incorporating material ductility and machine stiffness to accurately analyze AHSS steel grades and/or identify machine weaknesses.

Production Simulation

Using process line production simulation software to calculate production capacities. The software models the essential process limitations, accumulators, and time cycles of a line and simulates a large schedule of coils in sequence.

Wet Process Models

Using chemical, heat, and mass transfer models to calculate pickling, cleaning, rinsing, electoplating, heating, and drying.

Strength Analysis

Using refined techniques to effectively combine finite element analysis with AWS and AGMA codes for predicting fatigue failures in complex fabricated components.Technologies

improve, everything, always

Process Studies

Providing process studies and machine analysis with proprietary technology

Technical

Services

• Process Line Tension/Strip Transport Studies • Rolling Mill Capability • Roll Profiles • Mill Setup • Leveler Capability • Winding Optimization • Production Capacity • Project Development Engineering

Mechanical

Equipment

Analysis &

Redesign

• Roll and Shaft Failures • Frame Fatigue • Fixed and Flying Shears • Gearing and Geared Elongators • Overcoming Recurring Equipment Failures

On-line

Process

Setup and

Control

Models

• Tension Setup • Rolling Mill Level 2 Rolling Model • Rolling Mill Level 1 Bending Model